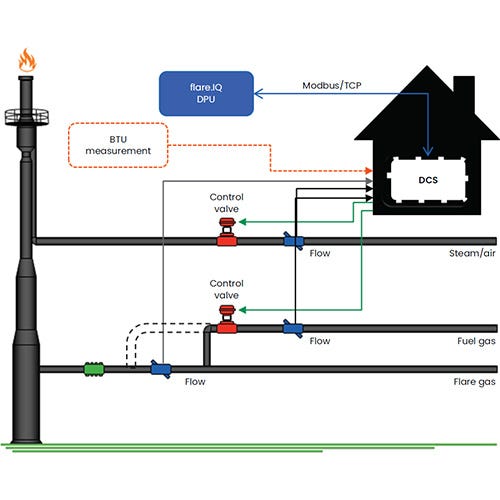

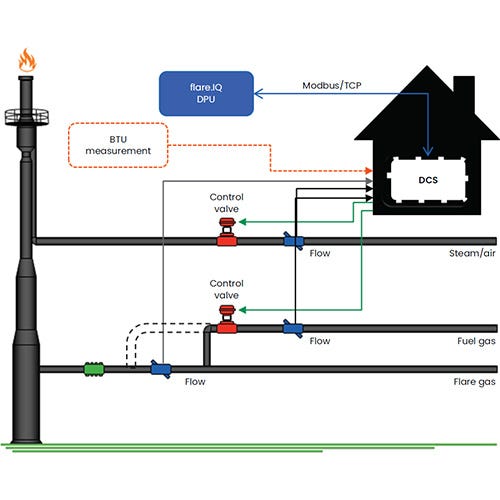

Panametrics' flare.IQ is a control computer that receives inputs and sends outputs to the customer’s distributed control system (DCS) via TCP/IP Modbus to control a flare’s fuel gas and steam supply valves. It is a complete turnkey hardware and software solution that enables regulatory compliance along with increased efficiency and reduced operating costs.

System hardware includes two 19” rack-mounting sheet metal modules. The top module is for power distribution and networking, including redundant power supplies, a pair of ethernet switches and other power equipment and cables. The bottom unit houses the compact fanless digital processing units (DPU), which control the flare stacks and verify flare flowmeters.

- Manages flare assets remotely 24/7

- Verifies flare meters remotely, eliminating the logistical and operational costs of technician support, scaffolding, and permit application associated with traditional flare verification

- Performs scheduled or on-demand digital validation of ultrasonic flowmeters installed on the vent gas line

- Pulls critical information about your flare system, including temperature, pressure, vent gas velocities, and gas composition to calculate the optimum levels of flare performance

- Provides accurate, real-time production floor data so you can intervene quickly and optimize flare combustion efficiency

- Identifies issues early with real-time access to combustion efficiency data on the production floor

- Optimizes flare operations, reduce emissions, and save costs

- Reduces methane slip emissions, minimizes costs from flaring operations, and improves transparency for flare operations