$750+ Orders on Lesman.com Ship Free via UPS Ground

Jordan Valve's Mark 86 ambitemp regulator controls steam tracing lines based on ambient temperatures to protect outdoor instrumentation, pipelines, and tanks from freezing.

The Mark 86 allows steam to flow through the tracer lines only when it is needed, then opens or closes when ambient temperature rises above or below the setpoint depending on action, so you don't pay for costly steam flowing into tracing lines when it's not needed.

- For worry-free control of steam trace lines in ranges 5° to 210° F (-15° to 99° C)

- Available in 1/2" to 2" sizes (DN15 to DN50) with threaded, flanged, socket weld, or butt-weld end connections

- Usually installed as a normally closed valve, but can be set as normally open to close when the ambient temperature rises

- Sealed weld actuator – No elastomer parts provides longer service life

- Sliding gate seats provide straight-through flow for reduced turbulence and quiet operation

- Short stroke for fast response and accurate regulation

- Easily interchangeable CVs up to 30

- ANSI Class IV shutoff

- Can be ordered in ductile iron, bronze, carbon steel or stainless steel body with Jorcote seats

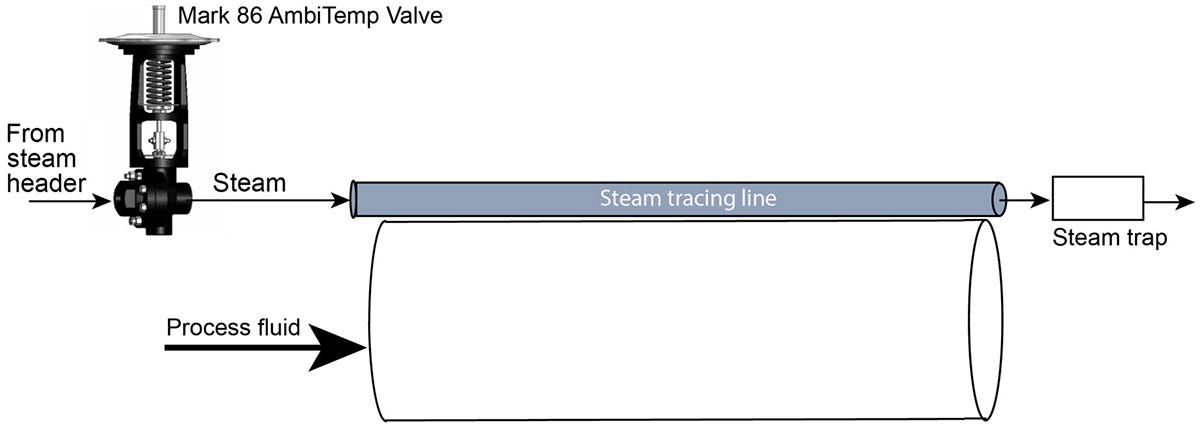

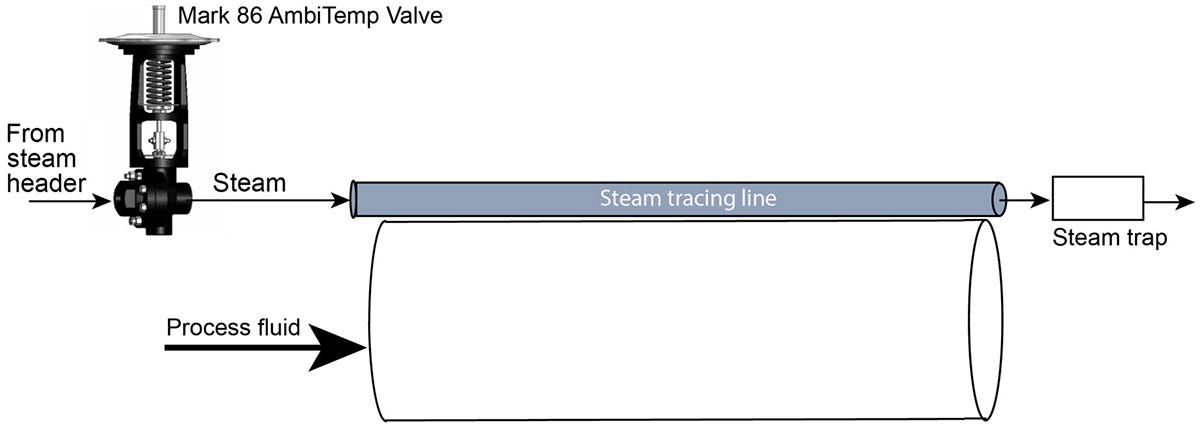

Steam Tracing for Pipe Protection

Steam tracing is used in chemical production and oil refineries where process fluids are transferred through outdoor pipelines with regularly changing ambient temperatures. Heat tracing or steam tracing is particularly important to protect the products from freezing, maintain product viscosity, avoid chemical separation or gas condensation, and prevent solidification or crystallization.

Ambient temperature is ever-changing throughout the seasons. When the temperature drops, it's time to turn the steam tracing system on so products don’t freeze, separate or become compromised due to low temperatures. And when the temperature rises, it’s time to turn the steam tracing off. Remembering when to turn steam tracing system on or off for seasonal temperature fluctuation is a test of the memory. One forgetful moment could have big implications.

Stories like this are common in the US Midwest where outdoor temperatures fluctuate widely: An industrial plant has a steam tracing water line installed on the pipeline, but an early freeze causes burst water lines when a plant operator fails to open the necessary steam tracing valves or is not aware of a weather forecast.

With steam tracing water lines, an actuator can measure and react to the ambient temperature. An operator could set the temperature regulator for 40° F (10° C), so the valve opens once the temperature drops below that setting. When the valve opens, steam flows to the tracing lines, minimizing the risk of freezing the water within the piping.

These ambient temperature (ambitemp) valves reduce the possibility of human error and provide dramatic utility cost savings. The same valve that opens at 40° F (10° C) will close as the ambient temperature rises above that level, so you're not paying for costly steam flowing into tracing lines when it's not needed.

Automating Steam Tracing with Mark 86 Regulators

Installing Jordan Valve's Mark 86 ambient temperature steam tracing valve means you don't have to remember seasonal on/off dates for steam tracing.

Mark 86 normally closed valve operation is fairly simple: A pre-measured amount of liquid fill is drawn into the thermal system filling the upper diaphragm chamber. As the ambient temperature increases, the liquid in the sensing chamber vaporizes and creates pressure on the sealed system. This pressure drives the valve stem, closing direct acting valves.

The Mark 86 requires no capillary or sensing bulb. Instead, its actuator serves as both sensing element and the power element. Mark 86 is designed using Jordan's unique sliding gate technology for superior response, wide range of Cvs and increased service life. They are available with several temperature ranges and line sizes.

Call Lesman inside sales for more information.