Jacoby-Tarbox in-line eductors are designed for in-line mixing, pumping or heating in process applications. In-line eductors are a cost-effective alternative to jet pumps, ejectors, venture pumps, siphon pumps, steam siphons, and injector pumps.

Jacoby-Tarbox in-line eductors are designed for in-line mixing, pumping or heating in process applications. In-line eductors are a cost-effective alternative to jet pumps, ejectors, venture pumps, siphon pumps, steam siphons, and injector pumps. They have no electrical components, so Jacoby-Tarbox eductors require no explosion proofing, making them optimal for hazardous locations.

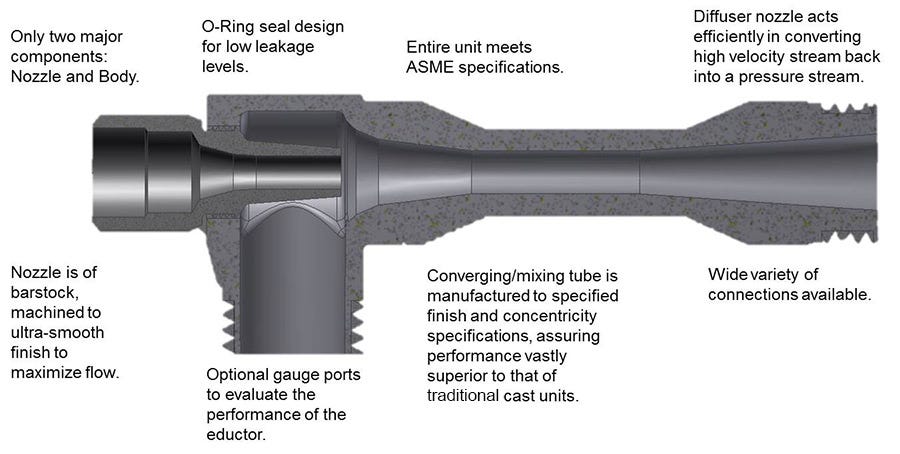

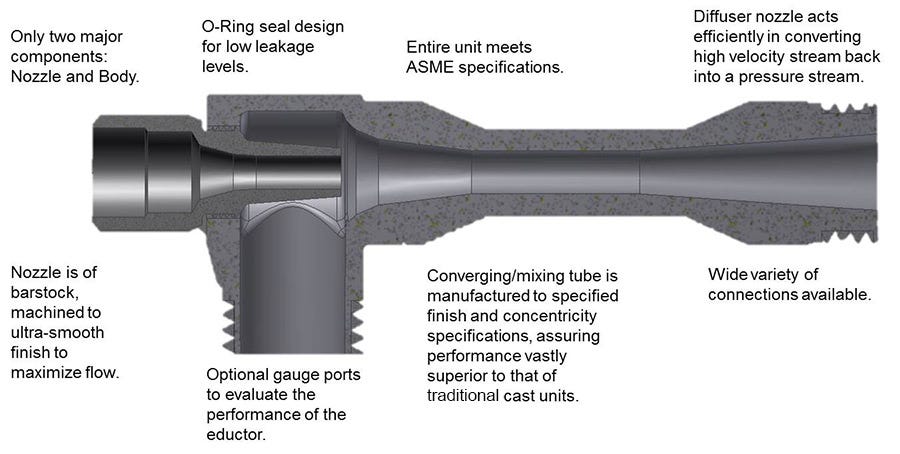

The eductor's smooth flow paths are critical for optimum performance. They also feature a reinforced mixing tube section to handle the stress of installation. All units are equipped with wrench flats to avoid damage during installation.

When you provide actual computational data, Jacoby-Tarbox can design a custom eductor for your specific mixing needs.

- Can be used in liquid, gas, steam or solid applications

- Materials available: Carbon steel, 316 stainless steel, bronze, PVC/CPVC, PVDF, Monel®, Hastelloy® C, and others

- Meets ASME specifications

- Easy installation and low maintenance