The system is designed to optimize any fruit or vegetable peeling process and consists of the camera unit, control module, and image processing software. It works in batch or continuous processes and determines when the product has been suitably peeled, helping you avoid over- or under-peeling and increases product throughput while minimizing product waste.

The PEELERCAM™ system consists of a highly sensitive Gigabit Ethernet camera with an integral LED light source, CANTY Vector Control Module (VCM), and image analysis software. It can be mounted via a single 6” Tri-Clamp® connection in enclosed peeling processes, or an overhead supporting arm or bracket in open systems.

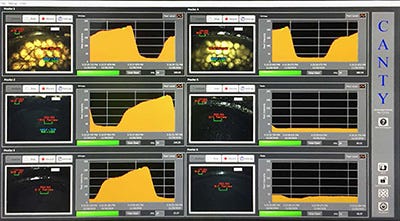

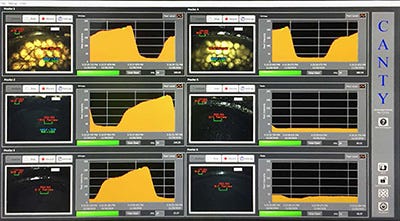

The live video feed is transferred to the VCM over a TCP/IP network connection and processed by image analysis software in real time recognizing the peel condition of the product. The VCM’s built in 4-20mA, OPC or Modbus TCP/IP capability provides direct communication with the user’s control system, allowing for a fully automated control of the peeling process.

- Measures the color intensity value (absolute value, 0 – 255), and rate of change (RoC) of that intensity value

- Vector Control Module (VCM) can support up to six PEELERCAM units

- Integral jet spray ring cleans the fused glass front cap of the PEELERCAM